Paint mist coagulant method

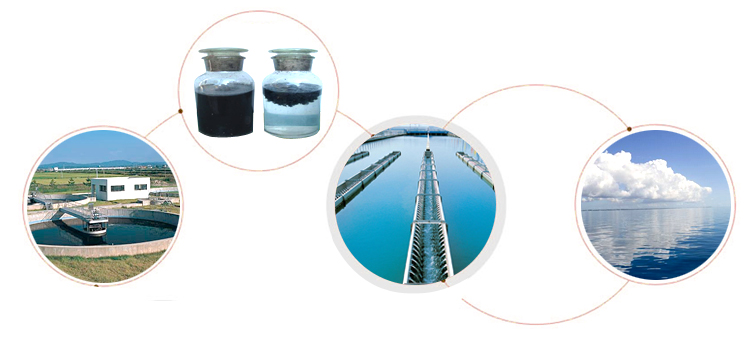

Paint mist coagulant wastewater treatment involves two processes, namely the destruction process and flocculation process. Destruction means the process to let colloid destablize and gathered into micro-flocculate, particle diameter change to 0.1- 1.0 mm after destruction; this is easy to realize the solid-liquid separation. Paint process not only includes the colloid destablize, also includes paint debonding. The destruction process of solvent-based paint is mainly debonding; water-based paint destruction process is mainly destabilization. Destructed particle is processed by polymer compounds again, and then it condenses to form clusters and rise rapidly, which is beneficial for the artificial or slag machine salvage. Treated water can be recycled; paint mist coagulant method has good effect, simple operation, and low processing cost.

The treated water can be recycled, mist coagulant method has good effect, simple operation, and the processing and low cost.

Zhejiang FengHong New Material Co., LTD., relying on bentonite industry technical strength and rich nonmetallic mineral resources, the company successfully develops paint mist coagulant products using bentonite as the main material. Compared with the other chemical products, it has the advantages of natural environmental protection, non-toxic effects, wide using range, and free from adjusting the PH value of water body. It has received widespread requirements from cars, furniture, metals etc. industries.