Most of the oilfields in our country use water injection method, with the increasing extraction time, water content of the crude oil also increase year by year, which can reach more than 90% in later period. The crude oil that contains a large amount of water injection produces a large amount of oily sewage after dehydration treatment through joint station. The main pollutants are the rest mineral oil during oil-water separation process and high-molecular polymer, surfactant and inorganic salts during production process, as well as a lot of suspended solids and mud. Extract oil sewage usually return to the ground after treatment when achieve industry standards. Part of the reinjection water is to meet the requirements of oil exploitation, the other part belong to invalid injection.

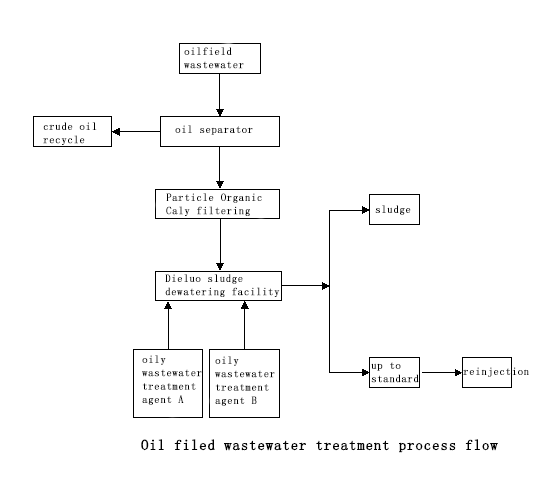

Sewage enter into storage tank first, then remove most of the oil and suspended solids in water after natural settling, the upper sump oil recycle regularly, add water purifier, coagulant and other agents into the multifunctional reactor out of water. By stirring and setting process, supernatant fluid is divided into two parts processing. Part of the water enters into the filter to reinjection through the tertiary reinjection. The other part of the water come into the integrated biological reactor for biological reaction, the reactor effluent to the sludge thickening tank, where conduct the sludge thickening sedimentation, supernatant go to setting pond, efflux outside once reach the standard. The sludge is lifted to the Dieluo sludge dewatering facility for dehydration processing by the mud pump.

Oil Field Wastewater Treatment

Wastewater treatment process description:

Oil separator: Oil separator pool is using the principle that small density oil buoyancy naturally, to separate and remove oily structures in the oily sewage. Wastewater enter into the separation tank from one side, and out from the other side. Because of the lower horizontal flow velocity in the pool, oils impurity that relative density less than 1.0 and in larger diameter will float under the buoyancy, and gather in the surface of the pool, then collect the oil slick through the oil tube set on the surface of the pool.

Filtration: Oil filtration is a synthesis process by small oil droplets cohesion and large oil droplets directly removal two mechanisms. Through filtration, adsorption of porous materials and then realize further oil-water separation. Filter material is the core part of the filter; it provides the surface for the suspended solids contact flocculation and dirt storage space. This project adopts the organic bentonite particles, which have very strong adsorption effect on dispersing oil particles and improve water quality.

Muddy water separation: Oily waste water treating agent A is the high-tech product researched and developed by our company independently. With strong ability of demulsification, it can effectively improve the water-in-oil (W/O) or oil-in-water (O/W) emulsion interfacial tension, and make wastewater in oil or colloidal particles lose stable repulsive force and attractive, working together with oily waste water treating agent B as adsorption bridging role, through condense dehydration of Dieluo facility, finishing oil/water separation finally.